- GENTILI SRL -

PRODUCTION

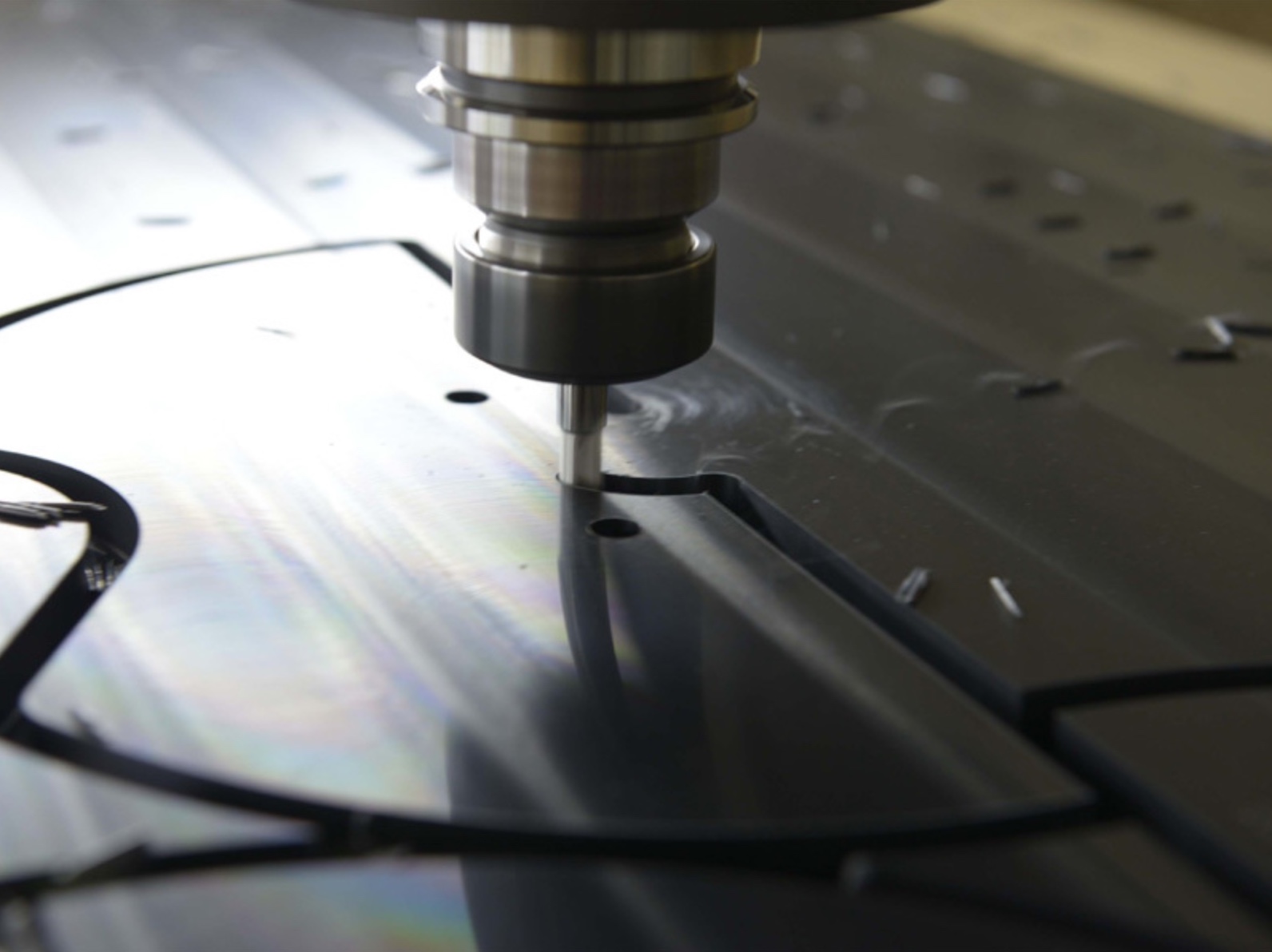

Tailored Production: Precision, Flexibility, Control

Every process is designed around the client’s needs

At Gentili S.r.l., we combine advanced technologies, a lean organizational structure, and over 50 years of experience to deliver tailor-made solutions for machining technical plastics, phenolic laminates, and light alloys.

Quality Control 4.0: Precision and Reliability Assured

At Gentili S.r.l., innovation is integral to our quality standards.

Our Quality Control department leverages Industry 4.0 advancements, utilizing state-of-the-art dimensional inspection tools, such as a high-precision digital height gauge and a 3D measuring arm.

This capability enables us to ensure every order is thoroughly verified and reliable.

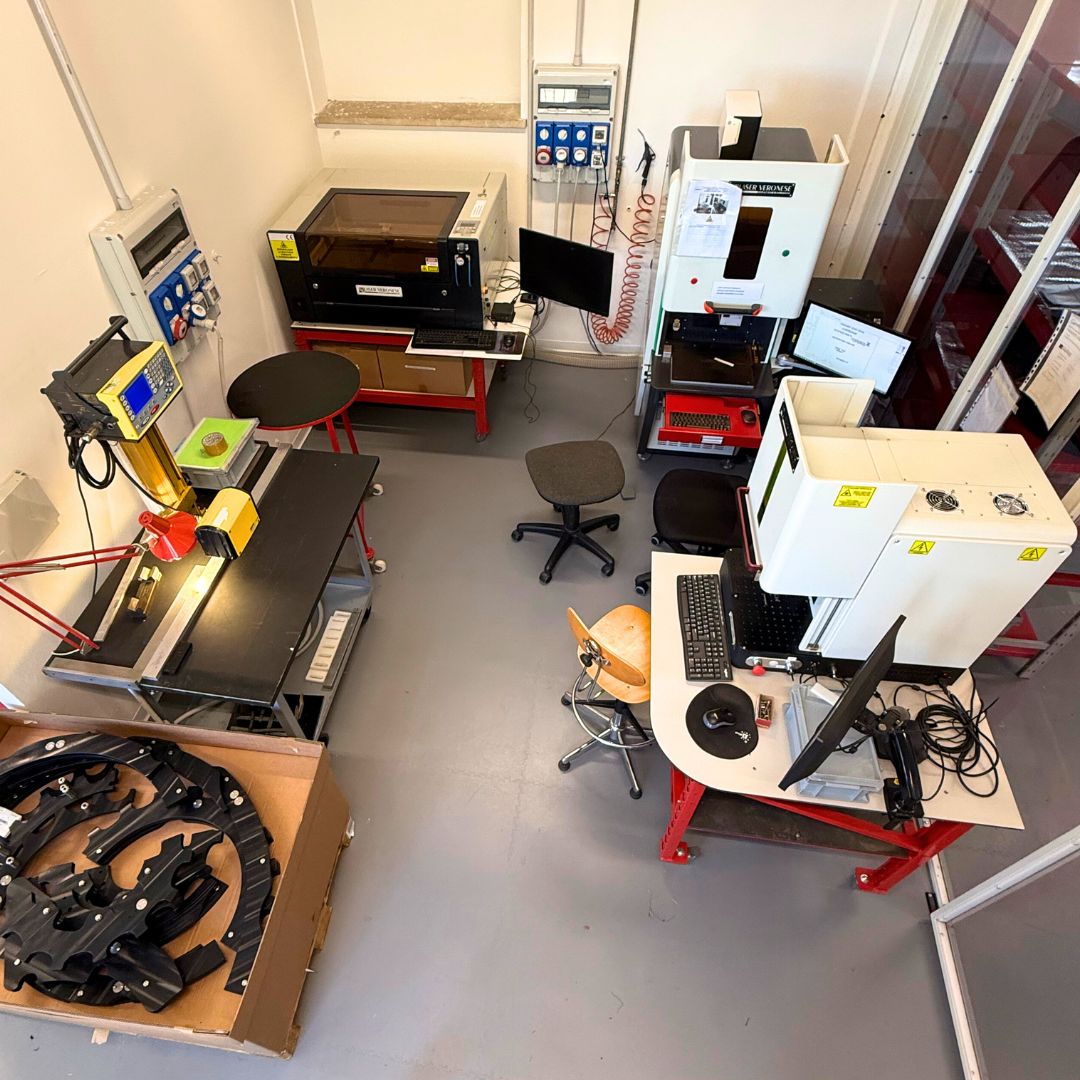

Industrial Marking for Traceability & Customization

We operate a dedicated marking department to ensure component traceability, identification, and personalization.

Our marking technologies include:

- Fiber and UV laser marking

- CO₂ laser marking

- Micro-dot marking

This versatility allows us to apply precise and durable markings on a wide range of technical plastics and light alloys.

OUR STRENGTHS

Full process control

From prototyping to final production, we guarantee top-quality at every step.

Custom Machining

We create complex technical products tailored to your specifications.

Specialized Production Areas

Dedicated zones for milling, drilling, cutting, assembly, and quality control.

Kit Assembly in Plastic and Light Alloys

Tailored assemblies that streamline integration into your production lines.